Applicable Industries:

Manufacturing Plant, Food & Beverage Factory, Farms, Energy & Mining, Metallurgy, Steel Factory, Industrial Gas

Showroom Location:

None

Condition:

New

Usage:

Liquid Oxygen Nitrogen Industrial Medical Oxygen

Production Rate:

100%

Voltage:

220v/380v/50-60hz

Weight:

Actual Weight

Dimension(L*W*H):

Actual Size

Warranty:

1 Year

Key Selling Points:

Modular Skid Design

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

1 Year

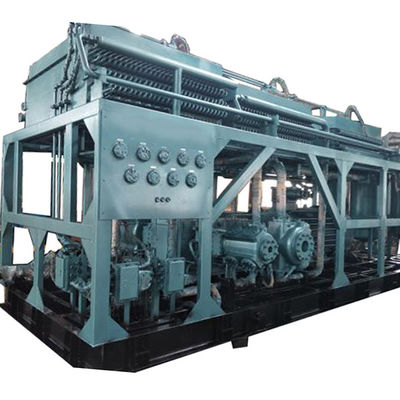

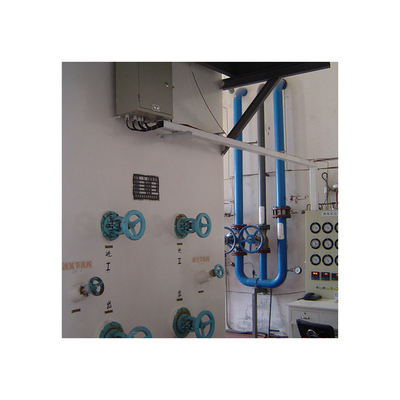

Core Components:

Pressure Vessel, Air Purifier, Cold Box, Pre Cooler, Turbine Expander

Product Name:

Small Liquid Air Separation Plant

Application:

Industrial And Medical Oxygen Nitrogen Production

Material:

Aluminum, Carbon Steel, Stainless Steel

Purity:

99.6% O2 For LOX, 10ppm O2 For LIN

Technology:

Low Pressure Cryogenic Rectifying By Turbine Expander

Type:

Skid Mounted

Capacity:

1 TPD

HS Code:

8419609090

Name:

Oxygen Nitrogen Generator

Keyword:

Low Work Pressure, Turbine Expander, 13X Molecular Sieve

Local Service Location:

Egypt, India, Russia, Ukraine, Uzbekistan

After-sales Service Provided:

Video Technical Support, Free Spare Parts, Online Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service

Certification:

ISO9001:2008

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!